Аудио-википедия

Аудио-википедия

База знаний по hi-fi и high-end технике и комплектующим, отзывы и впечатления

Инструменты пользователя

Боковая панель

Это старая версия документа!

CSS

Active loads and signal current control

The use of active loads (CCS’s) in vacuum tube amplifiers has several advantages over resistive loads. These including full mu of the tube, lower distortion, and greatly improved power supply noise rejection.

When using active loads the load line presented to the triode is a horizontal line versus the diagonal line seen by resistive loaded stages. Transformer and choke loading also provides a horizontal load line in the midrange frequencies but goes reactive at low frequencies where the inductance limits the performance and at high frequencies where the inter-winding capacitance limits the performance.

The horizontal line represents the load line when using a CCS plate load. The diagonal load line represents a 15K resistive plate load. Working off the too small graph we can determine roughly that with a 12 volt P-P input signal the resistive load would give an output voltage of 188 volts P-P where the CCS load would give an output voltage of 269 volts P-P. If you compare the spacing of the grid curves you can see that with the CCS load the lines are much more evenly spaced.

Active loads are also very good at increasing power supply isolation. The CCS appears as a very high impedance low reactance load. The ratio of the high impedance of the CCS against the plate resistance of the triode determines the power supply isolation (ripple rejection). I prefer the use of the term power supply isolation instead of ripple rejection as it offers a more comprehensive view of workings of the amplifier. The low reactance means the CCS will remain a high impedance load over a very wide range of frequencies.

Active loads are also a tool that can be used to control where the AC signal current flows. When active loads are coupled with shunt regulators, the use of large capacitors in the signal current loop can be avoided.

One of my design goals is to have the power supply responsible only for supplying DC current for the operation of the stages and to have the AC current paths separate from the power supply.

Conventional SE stage

In conventional SE circuits the power supply is an integral part of the signal current loop. This makes for a signal loop that has at minimum, 4 components in the AC path, the plate load, power supply capacitor, cathode bypass capacitor and the triode. In most cases, the cathode bypass cap and the final capacitor in the power supply are large capacitors, usually electrolytics that have less than stellar sonics. Another problem that plagues conventional SE circuits is poor power supply isolation.

SE stage with active load

When we add an active load the basic operation of the stage changes. Now the power supply only provides DC operating current as the CCS provides isolation between the power supply and the triode. With the CCS holding the current drawn from the power supply steady the demands on the power supply are greatly reduced.

The great power supply isolation provided by the CCS makes the design of the power supply much less critical. Depending on the performance of the CCS, power supply isolation of over 100dB is possible. It is not necessary to have super low ripple and noise with this kind of isolation available.

Another feature of having the current through the triode held constant by the CCS, we can dispense with the cathode bypass capacitor. The constant current flowing through the cathode resistor provides a constant DC voltage to bias the stage. Effectivly the stage operates with fixed bias.

This holds for light loads driven by the stage. If the next stage is a heavy load requiring current to be delivered the tube will come out of constant current operation. In RC and DC coupled circuits the predominant load is usually the miller capacitance of the next stage. The capacitive load causes the horizontal load line to become elliptical at high frequencies increasing the distortion. This could be one of the contributors to harsh, strident, grainy high frequency sound.

To overcome the loading issues a follower circuit can be used to isolate the load from the triode. The CCS’s I have designed have the capability of performing as a source follower without any modifications. This could be viewed as an advantage to having the voltage reference and current setting hardware at the bottom of the CCS.

Before moving on to the follower ideas, a basic understanding of CCS operation is necessary.

Overview of a simple CCS

One of the simplest CCS’s to setup uses a single mosfet. There are 2 kinds of mosfets that can be used to build CCS’s. Depletion mode mosfets are normally «on» and enhancement mode mosfets are normally «off». It only takes a single resistor to make a CCS with a depletion mode part where it takes a voltage source (battery) and a resistor to build a CCS from an enhancement mode mosfet.

To use a depletion mode mosfet as a CCS the fist step is to refer to the part’s data sheet. Find the performance curves plotting current Vs drain voltage. They will look like nice pentode plate curves. Look for the bias voltage at the current you want the CCS to operate at. The value of the current set resistor will be the bias voltage divided by the operating current. The value may need to be adjusted slightly to get due to turn-on voltage variations in the mosfets.

To use an enhancement mode mosfet as a CCS we need to provide a bias voltage (battery) to turn the mosfet on. You will need to refer to the data sheets to find what the turn-on voltage is at the required current. The value of the current set resistor will be the battery voltage minus the turn-on voltage of the mosfet.

The disadvantage to single mosfet depletion mode CCS’s is relatively poor performance. When using the depletion mode mosfet as a CCS the bias voltage available to set the current is usually 1 volt or less. The low bias voltage does not provide good feedback to stabilize the operating current.

When using enhancement mode mosfets with batteries to provide bias the voltage can be up to the gate voltage limit of the mosfet, typically 20 volts. The higher voltage provided by the batteries provides much better internal feedback in the CCS. This increases the performance by a large margin. Batteries can also be used with depletion mode mosfets to improve the performance of the CCS.

Another poor performance aspect of single mosfet CCS’s is high shunt capacitance. Mosfets look like great parts until you take into account their high capacitance issues. I suspect that the shunt capacitance is the source of most of the sound coloration’s that make CCS’s sound different.

The use of a cascade circuit configuration will greatly reduce the shunt capacitance and improve the DC performance of a CCS.

Performance in a cascode circuit improves because the upper mosfet isolates the lower mosfet from voltage variations. At higher frequencies where the capacitance issues come into play the AC leakage current that couples across the drain to the gate of the upper mosfet is routed back into the current summing node of the CCS, the source of the lower mosfet. There will be very little AC leakage current from the drain to gate of the lower mosfet, as it is isolated from the AC signal by the upper mosfet. With the upper mosfet handling the AC signal voltage the lower mosfet basically operates at DC.

Using a CCS as a combined CCS and mu follower

When an n-channel mosfet is used for a CCS we have an opportunity to get a second function almost for «free». The output signal can be taken from the source of the lower mosfet instead of the plate of the triode. Refer to the schematic above to see the circuit detail of where the signal is taken from.

When driving output triodes or interconnect cables that are high capacitance loads, this arrangement works very well. The driving triode is isolated from the load capacitance to maintain constant current operation at high frequencies and the next stage is driven from low source impedance.

The drawback to this arrangement is the current to drive the next stage comes from the power supply, it violates the design concept of separate paths for AC and DC.

CCS fed shunt regulators

A CCS feeding a VR tube forms a simple shunt regulator circuit that has excellent performance (and the glowing VR tubes look great too).

Shunt regulators work by varying the current they draw from a circuit to maintain a fixed voltage. If the voltage tries to increase the shunt regulator increases the current it draws. Conversely, if the voltage starts to decrease the shunt regulator decreases the current draw to hold the voltage stable. The simplest shunt regulator is the VR tube or «gas zener».

Depending on VR tube family the operating current can be from 3ma to 40ma. The miniature tubes generally are 3 to 30 ma while the octal tubes are 5 to 40 ma.

VR tubes are quite inductive. To improve the high frequency performance a small capacitor can be added in parallel with the VR tube. Most VR tubes have a maximum capacitance specification of .1uf. If the capacitance is increased above .1uf the VR tube and capacitor can form a relaxation oscillator and will start to oscillate. I have been using .056uf capacitors with good results.

A CCS fed shunt regulator is placed between the power supply and the CCS feeding the triode. This isolates the signal path from the power supply.

To setup a CCS fed shunt regulator in this application you set the upper CCS for the current that the lower CCS is set for plus the current to bias the VR tube. Assuming the lower CCS is set to deliver 10ma to the triode and the current desired in the VR tube is 15ma, the upper CCS would be set to deliver 25ma.

It is interesting to note that only the circuits using the mu output have the triode operating in true constant current mode. In the other variations of CCS loaded triodes where the signal is taken from the plate, the plate current varies in proportion with the load current.

CCS loading of output stages

Output stages are a different case. The CCS is used as a high performance replacement for the plate choke. The CCS offers performance that is simply not achievable with inductors.

The object is not to operate the triode at constant current but to provide the output stage with a constant bias current that does not change over the operating frequency range of the amplifier.

In this arrangement the output stage as a whole operates at constant current. With the triode working into the load presented by the output transformer. The sum of the AC currents through the triode and the primary of the output transformer will equal the DC current set by the CCS.

The use of CCS’s use in P-P stages

There are a couple of ways that CCS’s can be used in P-P stages.

CCS fed shunt regulator to feed the plates. This provides a stable clean supply for the stage.

A CCS can be used on the cathodes of a P-P input stage. This allows the input stage to perform the phase splitting duties.

Copyright Ó Gary Pimm 2003. All rights reserved

Варианты применения

April 14, 2008

Due to continued interest in building the self bias CCS and my lack of time to sell boards I've decided to release this version of board layout to the public domain. If you have batches of boards made up for whatever use drop me an email. I'd like to hear about what you use them for. You will find a zipped board file in the down loads section.

To use the board file you need to install the latest version of ExpressPCB then open the file. Ordering 1 mini board set using this file gets you 12 self bias CCS boards. You will need to use a large pair of shears to cut the boards apart.

You are responsible for determining the suitability of the CCS circuits for your intended purpose. The author is not responsible for personal injury or property damage caused by use of the information on these pages.

Updated 3/20/05

Here is the newest member of the CCS family. It was created by using the layout of the new battery biased CCS and replacing the batteries with the voltage reference from the Rev. 5 CCS.

With the new voltage reference the self bias CCS starts softly. Initially, the current is only that of the reference, .35ma. As the voltage reference charges up C5 the CCS starts to conduct. It takes ~20 seconds to reach full output.

For choosing the value of R1 the voltage range of the reference is 9.5 to 27 volts. The turn on voltage of the MOSFETs is approximately 3.5 to 4 volts so the voltage range seen by R1 will be in the 5.5 to 23 volt range. Allowing for the variations in SS parts a working range of 8 to 20 volts should be available. The design center for R1 is 14 volts.

If you want to minimize the voltage requirements of the CCS R1 should be chosen to deliver the desired current at the low end of the adjustment range. R14 can be reduced from 27K to 15K to lower the minimum voltage required by the CCS by 4.2 volts.

The tradeoffs of these changes are minor but present. Lowering the value of R1 reduces the local voltage feedback reducing the effectiveness of the CCS slightly. In circuits where the CCS is use as a plate load for triodes reducing the value of R1 increases the noise gain can increase the noise floor in low level circuits. The noise gain is basically the plate resistance of the triode divided by the value of R1. Reducing the value of R14 could increase the shunt capacitance by a small amount as Q1 will have less voltage across it. Decreasing the voltage across MOSFETs below 10 volts quickly increases the capacitance.

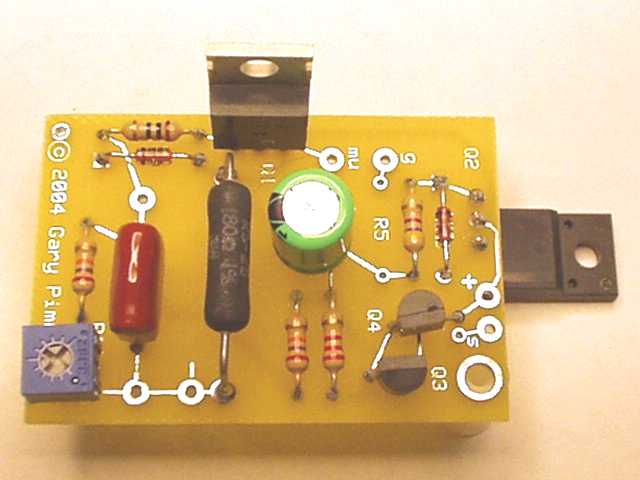

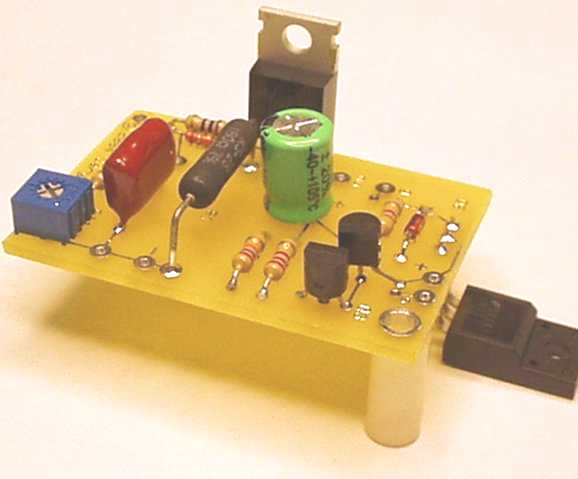

Here is a self bias board setup for MOSFET only operation with Q2 on the back of the board to allow using the top plate as the heatsink. When operating the CCS's over ~90ma Q1 needs to have a heatsink also, either a small clip-on heatsink or Q1 can be mounted on the back side just like Q2 is shown here.

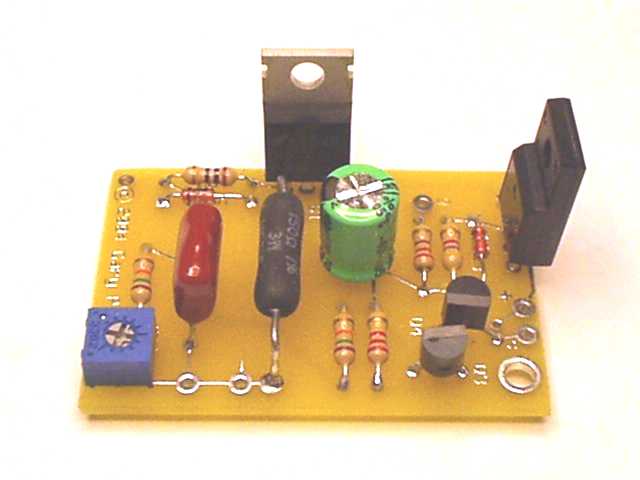

Another angle to help show how Q2 gets attached to the chassis

The standard TO220 package has enough lead length to allow for the use of either 10mm or 1/2 inch standoffs, depending on what standard is used in your country.

Here is the schematic of the self bias CCS.

The self bias board supports the option of using a Pentode for higher voltage/power/performance applications. This is basically the same circuit as the Rev. 5 with the Pentode support parts mounted off the board.

Here's an image of a self bias board setup for operation with a Pentode in an Amity amplifier feeding the VR tube on the input stage. As it is setup for minimum voltage operation, note that R10 and R14 have been lowered to 15K each. With R3 having a value of 7.5K this will deliver 60ma with between 150 and 325 volts across the CCS. Changing R3 to 15K changes the operating range to 185 to 360 volts. The minimum voltages are the point where the grid bias of the Pentode drops to -1 volt. The maximum voltages are where Q2 reaches 1 watt dissipation, the max for operation without a heat sink. Also note that the drain lead of Q4 is inserted into the board hole that is connected to the «S» terminal.

Here's an image of the input stage CCS setup using an EL34 Pentode in Lynn's Karna amplifier. The CCS is used to feed the VR tube shunt regulator for the input stage.

Here is the schematic showing the board setup with a Pentode

There are a couple of ways to choose the value of R3. In some of the earlier Pentode versions there is a mathematical formula to try to calculate the value of R3. It's quite messy to use and you still have to guess at at least 1 of the parameters. Personally, I start with a value of 22K and see what happens. If the grid bias of the Pentode is greater than 10 volts you can increase the value of R3. If the grid bias of the Pentode is less than 2.5 volts you will want to decrease the value of R3. It usually only takes a few tries to get dialed in. The thing to watch is to make sure that the grid bias of the Pentode does not drop below -1 volt at the lowest voltage the CCS will see in normal operation.